|

制程能力及检测参数 |

|||||

|

序号 |

ITEM |

Technical capabilities |

Illustration |

||

|

PCB |

Rigid-Flex PCB |

FPC |

|||

|

1 |

层次 |

1-64 layers |

2-30 layers |

1-20 layers |

|

|

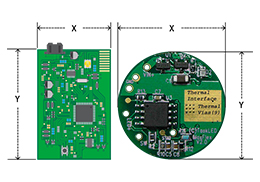

2 |

最大尺寸 |

1200mm*610mm |

1200mm*490mm |

5000mm*490mm |

|

|

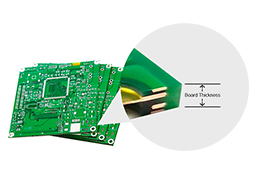

3 |

板厚 |

0.15mm--10.0mm |

0.15mm -10.0mm |

0.06mm -1mm |

|

|

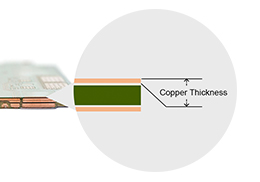

4 |

铜厚 |

12um-420um |

12um-210um |

12um-105um |

|

|

0.3OZ--12OZ |

0.3OZ - 6OZ |

0.3OZ - 3OZ |

|||

|

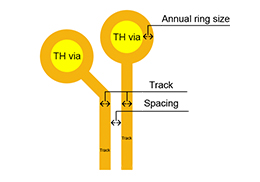

5 |

最小线宽/线距 |

0.05mm/0.05mm |

0.05mm/0.05mm |

0.035mm/ 0.045mm |

|

|

2 mil /2 mil |

2 mil /2 mil |

1.4 mil /1.8 mil |

|||

|

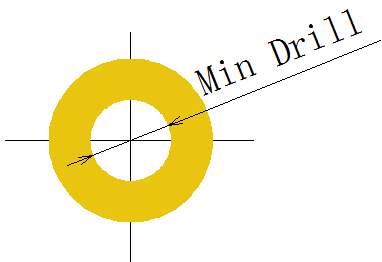

6 |

最小孔径 |

0.1mm |

0.1mm |

0.07mm |

|

|

4 mil |

4 mil |

2.8 mil |

|||

|

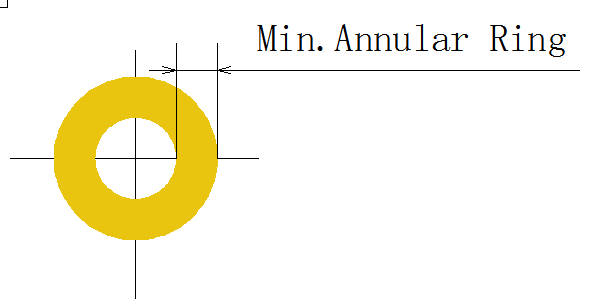

7 |

最小孔环 |

0.1mm |

0.1mm |

0.07mm |

|

|

4 mil |

4 mil |

2.8 mil |

|||

|

8 |

PTH孔孔径差 |

±0.05mm |

±0.05mm |

±0.05mm |

|

|

2 mil |

2 mil |

2 mil |

|||

|

9 |

NP TH孔孔径差 |

±0.05mm |

±0.05mm |

±0.05mm |

|

|

2 mil |

2 mil |

2 mil |

|||

|

10 |

孔位公差 |

±0.05mm |

±0.05mm |

±0.05mm |

|

|

2 mil |

2 mil |

2 mil |

|||

|

11 |

V-CUT角度 |

∠20-90° |

∠20-90° |

/ |

|

|

12 |

最小V-CUT板厚 |

0.25mm |

0.25mm |

/ |

|

|

10 mil |

10 mil |

/ |

|||

|

13 |

外型公差 |

±0.08mm |

±0.08mm |

±0.05mm |

|

|

3.15 mil |

3.15 mil |

2 mil |

|||

|

14 |

最小盲/埋孔 |

0.1mm |

0.1mm |

0.07mm |

|

|

4 mil |

4 mil |

2.8 mil |

|||

|

15 |

塞孔 |

0.15mm-0.5mm |

0.15mm-0.5mm |

/ |

|

|

6 mil- 20 mil |

6 mil- 20 mil |

/ |

|||

|

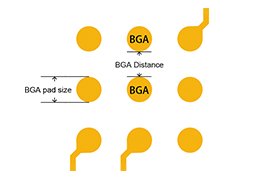

16 |

最小BGA |

0.2mm |

0.2mm |

0.2mm |

|

|

8 mil |

8 mil |

8 mil |

|||

|

17 |

材质 |

FR4板(指定品牌物料:如建滔、生益、联茂、南亚、台光台耀等)、高频板、铁氟龙板、陶瓷板、罗杰斯板等等 |

|

||

|

FR 4(designated brand materials:such as KB, Sheng yi, IT EQ, NANYA, EMC, CENS and soon) , high |

|

||||

|

18 |

表面处理 |

沉金/防氧化/镀金(软/硬)/喷锡/沉银沉锡/镀锡/碳油/金手指 |

|

||

|

immersion gold/OSP/plating Gold(soft/hard) /hotair leveling(HAS L) /immersion Silver/immersion |

|

||||

|

19 |

翘曲度 |

≤0.75% |

|

||

|

20 |

通断测试 |

50--300V |

|

||

|

21 |

可焊性试验 |

245±5℃, 3sec Wetting area least 95% |

|

||

|

22 |

热冲击试验 |

288±5℃, 10sec, 3 cycles |

|

||

|

23 |

离子污染测试 |

Pb, Hg, Cd, Cr(V) , PBB, PBDE六项均小等于1000ppm |

|

||

|

Pb, Hg, Cd, Cr(VI) , PBB, PBDE six items are less than 1000ppm |

|

||||

|

24 |

附着力测试 |

260℃+/-5, 10S, 3 times |

|

||

|

25 |

特殊工艺 |

半孔、高Tg板、混合压板、无卤素板、超薄超厚板、邦定、阻抗、蓝胶、碳油、电厚金、镍钯金、金手指、 |

|

||